Request Your Free A1 Design For Galvanizing Wall Chart

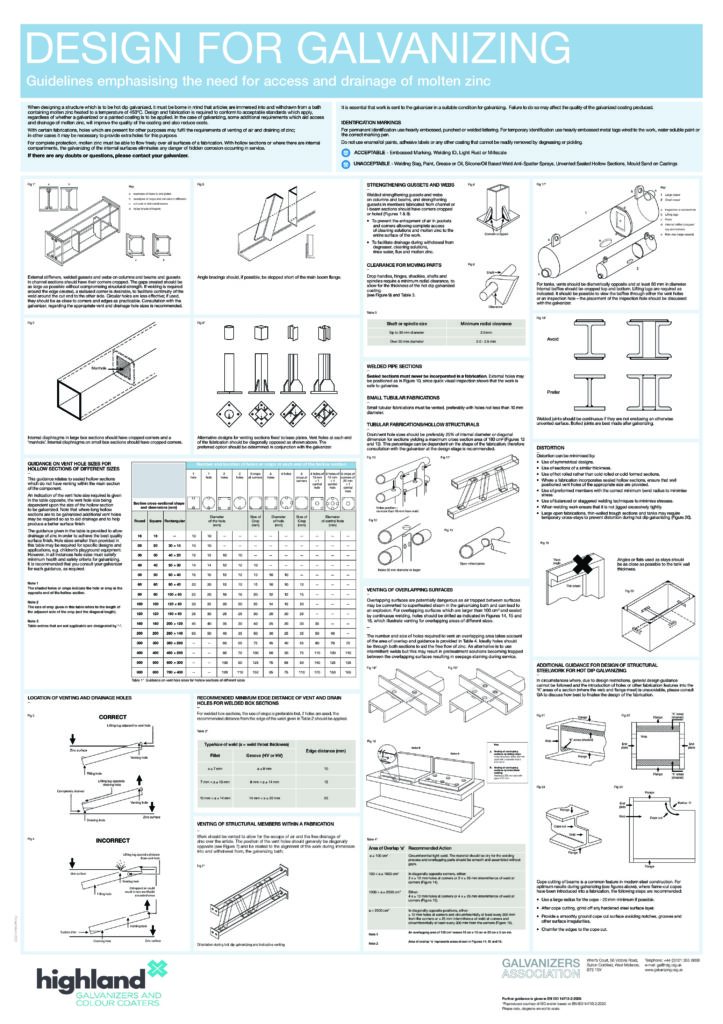

When designing a structure which is to be hot dip galvanized, it must be borne in mind that articles are immersed into and withdrawn from a bath of molten zinc heated to a temperature of 450ºC.

For complete protection, molten zinc must be able to flow freely over all of a fabrication. In the case of galvanizing careful consideration at the design stage will aid access and drainage of molten zinc which will improve the quality of the coating and also reduce costs. With hollow sections or where there are internal compartments, the galvanizing of the internal surfaces also eliminates any danger of hidden corrosion occurring in service.

This poster has been specifically created to help guide all our customers on the importance of venting and draining that should be considered at the design stage.

To get your free copy please fill in the enquiry form below with your details and we will post one out to you.