Colourgalv

The only hot dip galvanizing and powder coating system, with a unique multistage pre-treatment process, available under one roof in Scotland.

What is Colourgalv?

Colourgalv is a duplex coating that combines the corrosion protection benefits of hot dip galvanizing with the aesthetic beauty and colour of powder coating. We are able to carry out colour galvanizing in locations including Glasgow, Dundee, Edinburgh, Aberdeen, throughout Scotland and beyond. Colourgalv uses hot dip galvanizing as a basecoat (1) to ensure that every surface of the steel is protected from corrosion. The galvanized material is then subjected to a multi-stage in house pre-treatment process before the addition of a Polyester powder coating topcoat (3) that adds additional protection whilst also providing a colour and texture.

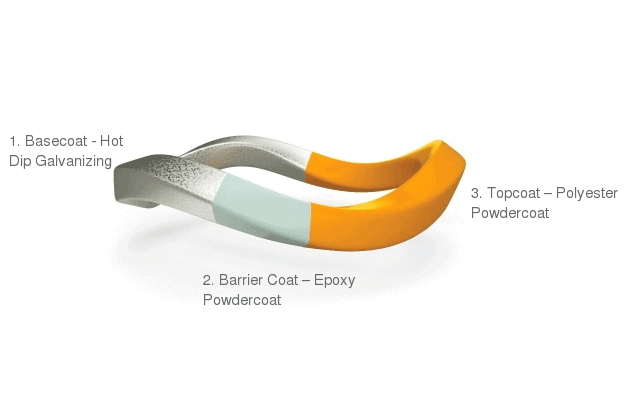

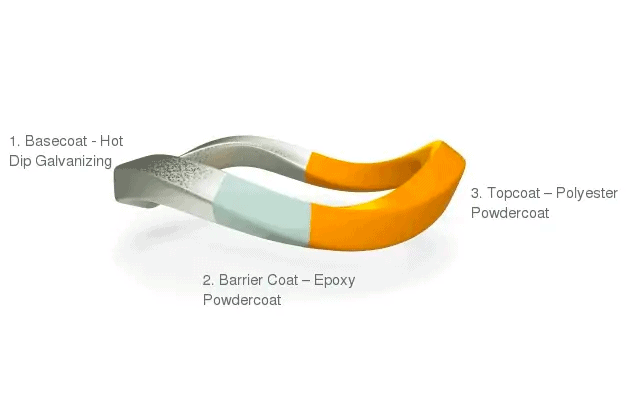

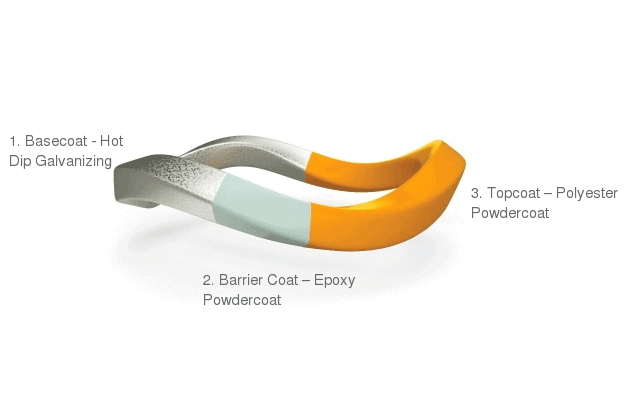

What is Colourgalv Marine?

Colourgalv Marine is our premium triplex coating that utilises the same performance benefits of hot dip galvanizing (1) and polyester powder coating (3) but adds an additional epoxy barrier coat (2) between the galvanizing basecoat and powder topcoat. This ensures the zinc coating does not oxidise in salt rich or harsher environments.

Enquire now about our Galvanizing, Colourgalv and full range of services.

Watch Our Videos About Power Coating…

Colourgalv Benefits

Projects we are proud to have been involved in …

Ropeworks

Belfast Rise

Connor’s Court, Brighton

Commonwealth Games

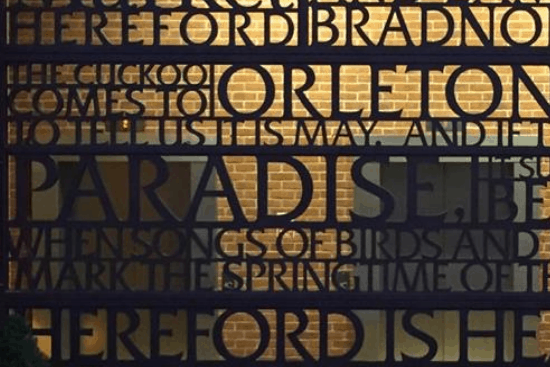

Old Market Hereford

Colour Chart

Whilst Colourgalv is available in any colour, the three stock colours illustrated below are the most popular, lowest priced and enable the quickest turnaround for your material, including our Xpress Colourgalv service.

Black

RAL 9005 Matt…

Anthracite Grey

RAL 7016 Matt…

Moss Green

RAL 6005 Matt…

Colourgalv Custom

By selecting Colourgalv Custom we have the ability to coat your material in any RAL and BS code of your choosing, a selection of which are illustrated below. This would also include a colour matching facility for existing colours.

Yellow Green

RAL 6018 Gloss…

Window Grey

RAL 7040 Matt…

Traffic Red

RAL 3020 Gloss…

Light Grey

RAL 7035 Matt…

Slate Grey

RAL 7015 Matt…

Mahogany Brown

RAL 8016 Gloss…

Signal Blue

RAL 5005 Gloss…

Traffic White

RAL 9016 Satin…

Basalt Grey

RAL 7012 Matt…

Leaf Green

RAL 6002 Gloss…

Zinc Yellow

RAL 1018 Gloss…

Ultramarine Blue

RAL 5002 Matt…

Colourgalv Marine

For coastal and offshore environments Colourgalv Marine is our premium triplex coating. It utilises the same superior corrosion protection benefits of a hot dip galvanizing basecoat and a polyester powder topcoat with addition of an epoxy barrier coat between the galvanized surface and the topcoat. This ensures that the zinc coating does not oxidise in the salt rich environment thus prolonging the overall protection on your material.